OPGW fiber optic cable installation guide

Definition and Application of OPGW

OPGW (Optical Ground Wire) optical cable is a special type of cable that combines fiber optic communication and power transmission. It is mainly installed on the top of high-voltage transmission lines, serving as a lightning rod and providing high-speed data transmission channels. Due to its dual functionality, OPGW optical cables are widely used in power companies and communication service providers to meet the needs of modern smart grids and communication networks.

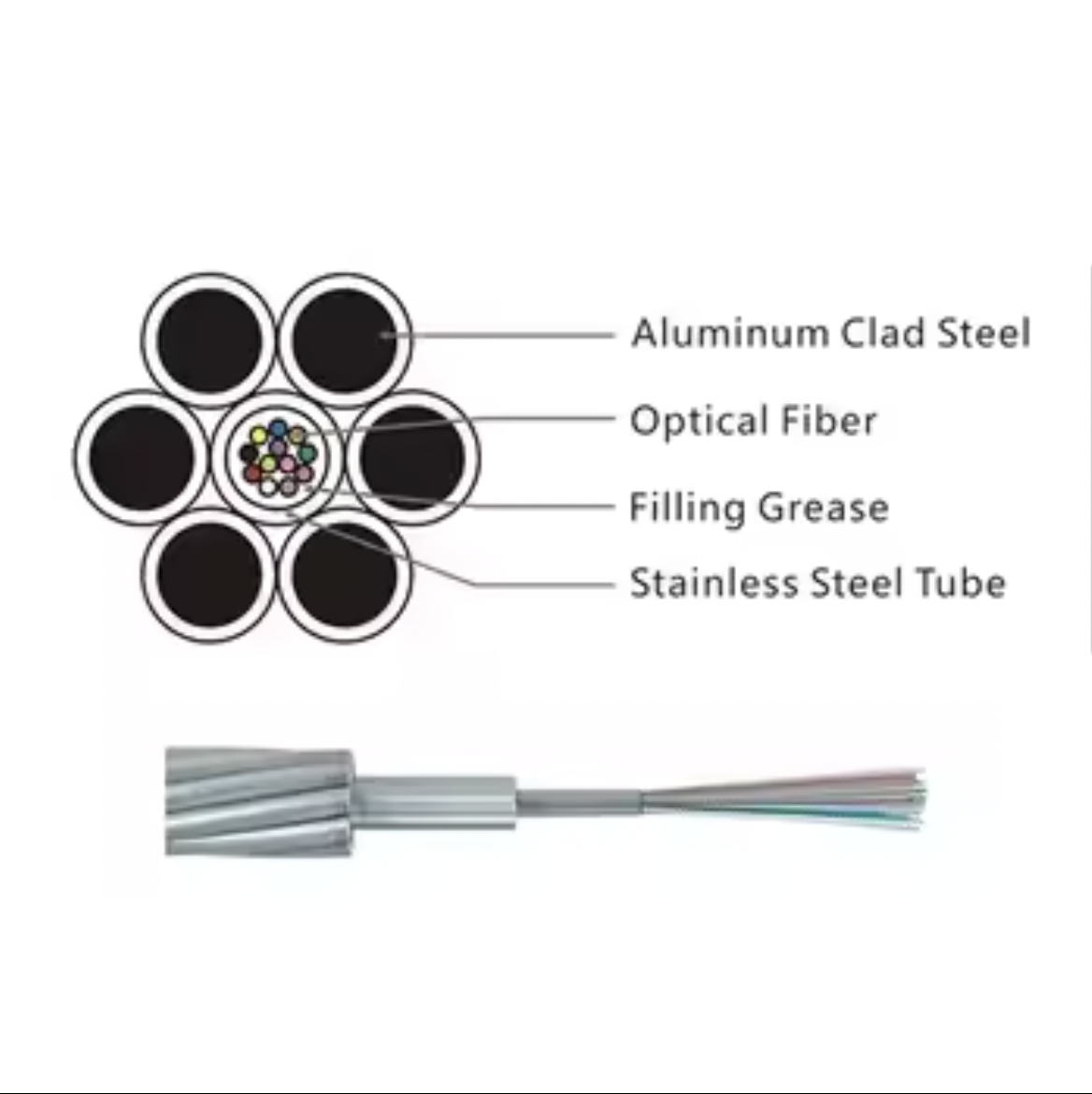

###Structure of OPGW optical cable

The structure of OPGW optical cable consists of an outer layer of metal wire and an inner layer of optical fiber. Metal wires are mainly used to bear mechanical loads and provide lightning protection, while the inner layer of optical fibers is used for data transmission. According to design requirements, the structure of OPGW optical cables can vary, generally divided into aluminum clad steel type, aluminum alloy type, and steel pipe type. Each type has its unique advantages to adapt to different application scenarios.

Preparation work before installation

Project Planning and Design

Before starting the installation of OPGW optical cables, detailed project planning and design are required. This includes determining the installation route, evaluating environmental conditions, selecting appropriate types of OPGW optical cables, and developing detailed construction plans. The key tasks during the planning and design phase include:

1. Route Survey : Conduct a detailed topographic survey and environmental assessment of the installation route to determine the optimal installation path.

2. Technical specifications * *: Based on survey results and project requirements, develop technical specifications, select appropriate OPGW cable types and installation methods.

3. Construction Plan * *: Develop a detailed construction plan, specifying the tasks, schedule, and required resources for each construction stage.

Preparation of installation equipment and tools

Installing OPGW optical cables requires the use of a series of professional equipment and tools, including fiber fusion splicers, traction machines, tension machines, climbing equipment, safety equipment, etc. Before installation, it is necessary to ensure that all equipment and tools are in good condition and provide necessary training to construction personnel to ensure the safety and efficiency of the construction process.

Installation process

Preparation work

Security check

Before starting installation, a comprehensive safety inspection must be conducted to ensure that the construction environment meets safety standards. This includes checking whether there are safety hazards around the line, whether construction personnel are wearing necessary safety equipment, and whether construction equipment is operating normally.

Fiber optic cable preprocessing

OPGW optical cables may be damaged during transportation and storage, therefore pre-treatment is required before installation. This includes checking whether the optical cable is intact, cleaning the surface of the cable, and performing necessary protective treatment on the cable.

Installation steps

Pole and traction

1. Pole erection : According to design requirements, pole shall be erected at the designated position of the line. When erecting the pole, it is necessary to ensure the stability and verticality of the tower.

2. Traction optical cable : Use a traction machine to pull the OPGW optical cable from the starting point to the endpoint. During the traction process, it is necessary to control the tension of the optical cable to avoid damage.

Tension and fixation

1. Tension Control : Use a tension machine to control the tension of the optical cable, ensuring that the tension of the cable during installation meets the design requirements. Excessive tension can cause damage to the optical cable, while insufficient tension can affect the installation effect of the optical cable.

2. Fixed optical cable : Fix the optical cable on the tower using a dedicated fixing fixture to ensure it is firmly fixed.

Fiber optic fusion and testing

1. Fiber Fusion Splicing : Use a fiber fusion splicer to perform fiber fusion splicing on optical cables. During fusion splicing, it is necessary to ensure the alignment accuracy of the fibers to ensure the quality of fusion splicing.

2. Fiber optic testing : Use a fiber optic tester to test the fused fiber optic and check if the transmission performance of the fiber optic meets the design requirements. Including fiber attenuation testing, fiber loss testing, etc.

Inspection and maintenance after installation

Installation quality inspection

After installation, a comprehensive inspection of the installation quality of OPGW optical cables is required. This includes checking whether the fixing of the optical cable is firm, whether the fiber fusion is qualified, and whether the fiber transmission performance meets the requirements. By inspection, ensure that the entire installation process complies with design specifications and technical standards.

Regular maintenance and upkeep

In order to ensure the long-term stable operation of OPGW optical cables, regular maintenance and upkeep are required. This includes regular inspection of the fixing status of the optical cable, testing of the transmission performance of the optical cable, and cleaning of dust and dirt on the surface of the optical cable. Through regular maintenance, potential problems can be identified and resolved in a timely manner, extending the service life of OPGW optical cables.

Common problems and solutions during installation

Damaged optical cable

During installation, the optical cable may be damaged due to improper operation or external force. For damaged optical cables, timely repair or replacement is necessary. The specific methods include:

1. Partial repair : For optical cables that are not severely damaged, partial repair can be performed. The repair methods include fiber optic fusion, using optical cables to repair sleeves, etc.

2. Replace optical cable : For severely damaged optical cables, it is recommended to replace them with a new one. When replacing, it is necessary to ensure that the specifications and performance of the new optical cable are consistent with the original cable.

Poor fiber fusion splicing

Fiber optic fusion is an important part of OPGW cable installation, and the quality of fusion directly affects the transmission performance of optical fibers. Common issues with poor fiber fusion include inaccurate alignment and inappropriate fusion temperature. The solutions include:

1. Re fusion : For optical fibers with poor fusion, re fusion is required. When re fusing, attention should be paid to the alignment of the optical fiber and the control of the fusion temperature.

2. Use high-quality equipment : Use high-quality fiber fusion splicers and auxiliary tools to improve fusion quality.

Fiber optic cable not securely fixed

Loose fixation of optical cables can cause them to move or be damaged during use. The solutions include:

1. Use specialized fixing fixtures : Use specialized optical cable fixing fixtures to ensure that the optical cable is securely fixed.

2. Strengthen fixing points : Add fixing points at key positions of the optical cable to improve its stability.

Conclusion

The installation of OPGW optical cables is a complex and meticulous project that requires strict planning and design, precise construction operations, and scientific maintenance and upkeep. Through the introduction in this article, we hope to provide some valuable references for relevant practitioners to help them better complete the installation task of OPGW optical cables and ensure the efficient and stable operation of power and communication networks.